Mobile Wastewater Treatment Plant Type PURITAINER

The BIOGEST® PURITAINER is a mobile wastewater treatment plant based on the SBR process for the biological treatment of domestic sewage. The PURITAINER is manufactured as a norm container including the complete technical equipment for the biological purification of wastewater. This design facilitates transport and the system is ready for connection on site due to the complete pre-assembly in the factory.

The use of proven system technology makes the PURITAINER very reliable and easy to use. The operation runs fully automatically and offers a permanently high cleaning performance.

Application possibilities

PURITAINER can be used anywhere where domestic wastewater is to be biologically purified. Ideal application cases are camps, housing estates, hotels, restaurants, hospitals and sanatoriums, barracks, campsites and holiday villages. The well-engineered PURITAINER wastewater treatment plant design ensures that the purification performance is high enough for the purified wastewater to be discharged into rivers, lakes or other waterways without problems despite the often unfavourable operating conditions associated with smaller connected loads.

The wastewater purified in the PURITAINER can of course also be sustainably reused, for example in the irrigation of green areas, for concrete manufacturer or additions to cooling water. These are interesting economic aspects, especially in countries with limited water reserves. In such cases, the PURITAINER wastewater treatment plant can be supplemented with a disinfection stage if necessary.

Functionality

PURITAINER are fully biological sewage treatment plants and work according to the activated sludge process, a treatment principle with which a high level of safety, flexibility and performance can be guaranteed. The good coordination of our system design with the selected SBR process technology ensures uncomplicated operation and constant cleaning performance, even with fluctuating system loads.

The advantages

- Rapid delivery through use of system components

- Easy transportation

- Ready-to-delivery through complete pre-assembly

- Easy installation

- Robust and proven technology

- Simple operation

- Fully automatic plant operation

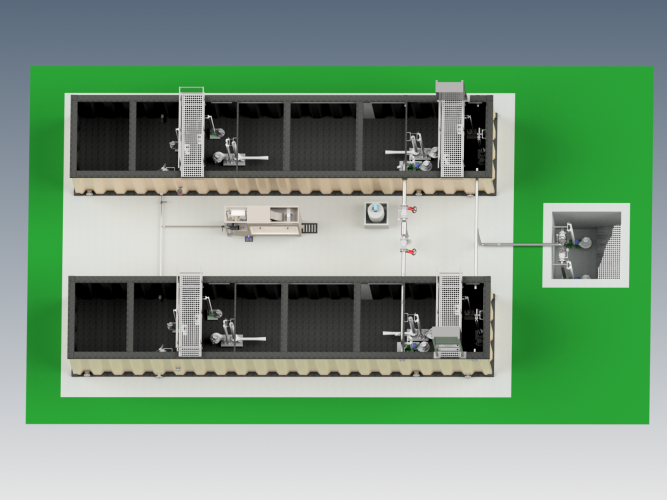

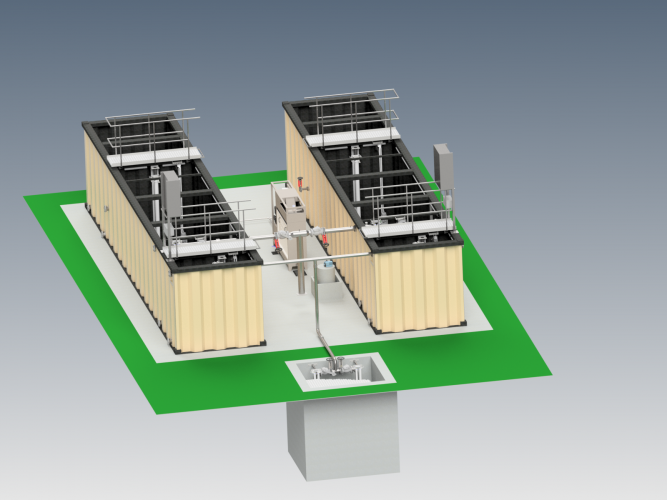

- Expandability through modular arrangement

- Repeated use of mobile applications

- Consistently high cleaning performance

- Compensation of hydraulic shock loads through SBR process technology

Construction

The BIOGEST® PURITAINER can be manufactured in various system sizes so that they can be used for loads up to approx. 250 PE. For larger connected loads, the PURITAINER can also be used modularly.

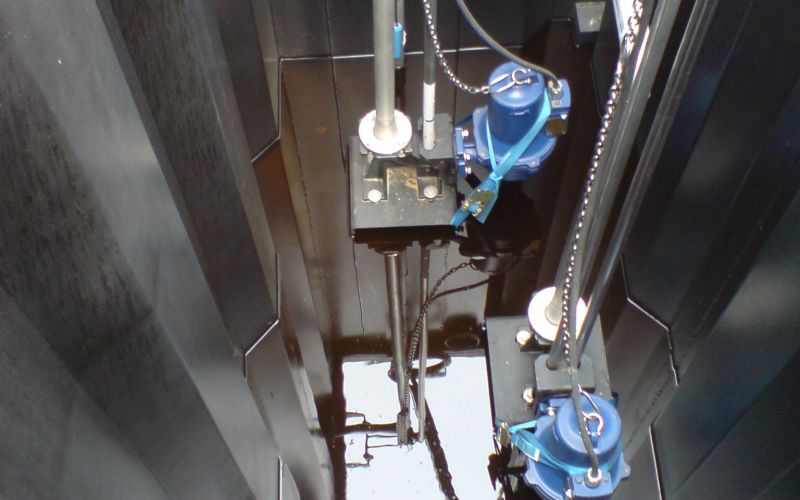

The PURITAINER is made of corrosion-protected steel. The simple execution of repairs and the low weight compared to concrete are decisive advantages. Corrosion protection is also a top priority for the PURITAINER.

After thorough sandblasting, all steel parts are coated with a coating specially developed for hydraulic steel construction. The applicable national regulations or tender conditions will of course be considered.